Regarding pipe repairs, two popular alternatives often considered are pipe bursting and pipe lining. These solutions are less disruptive and more economical than traditional dig-and-replace techniques. This blog will examine pipe bursting vs. pipe lining and what you should look for in a pipe repair solution.

Understanding Pipe Bursting: A Modern Trenchless Pipe Replacement Technique

A trenchless technique for installing new pipes instead of outdated, damaged ones is pipe bursting. This professional sewer repair service involves breaking the existing pipe while pulling a new one through the space created. Specialized tools, like a bursting head fastened to a pulling rope, are used to achieve it.

Pros of Pipe Bursting

Efficient Replacement: Pipe bursting allows for efficiently replacing old or damaged pipes with minimal excavation.

Increased Flow Capacity: Since new pipes are typically more significant than the old ones, pipe bursting can improve flow capacity.

Longevity: The new pipes installed through pipe bursting are durable and can last several decades.

Less Disruption: Compared to traditional dig-and-replace methods, pipe bursting causes less disruption to landscapes, roads, and structures.

Cons of Pipe Bursting

Initial Cost: Pipe bursting can be more expensive upfront due to the equipment and labor involved.

Limited Application: It may only be suitable for some types of pipe materials and configurations.

Site Accessibility: Access to the site and clearance for equipment may be challenging in some locations.

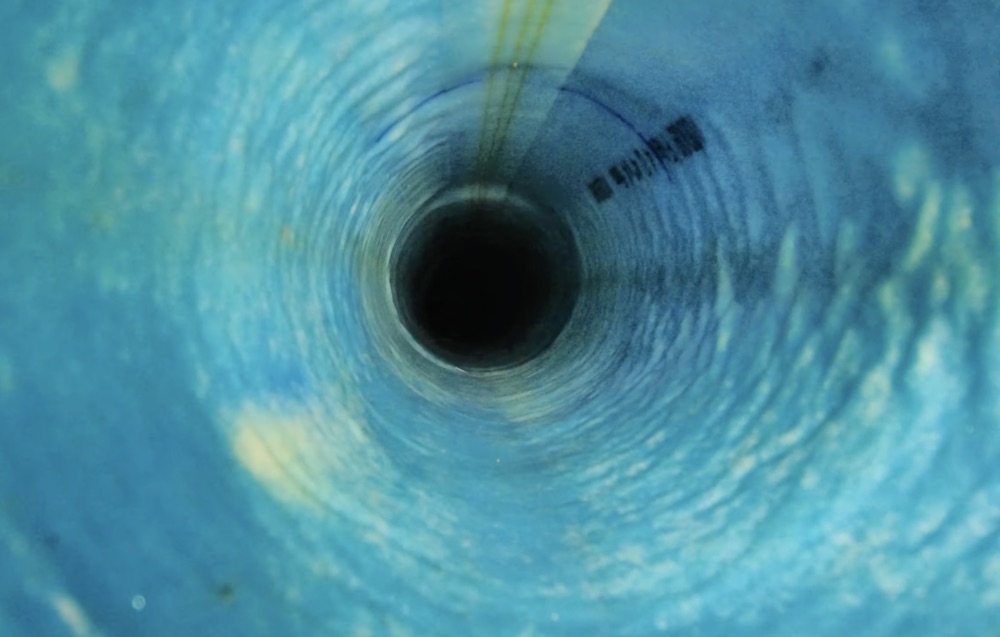

Exploring Pipe Lining: Advancements in Cured-in-Place Pipe Rehabilitation

Another trenchless rehabilitation technique is pipelining, also called cured-in-place pipe (CIPP) lining, which entails constructing a new pipe inside the corroded original pipe. It is accomplished by putting a flexible liner coated in resin within the old pipe and allowing it to cure.

Pros of Pipe Lining

Cost-Effective: Pipe lining can be more cost-effective than pipe bursting, especially for smaller-diameter pipes and less severe damage.

Versatility: It works with various pipe materials, including PVC, clay, and concrete.

Minimal Disruption: Like pipe bursting, pipe lining causes minimal disruption to the surrounding area.

Improved Flow: The lined pipe’s smooth interior surface helps increase flow and lower the chance of obstructions.

Cons of Pipe Lining

Limited Diameter Increase: Pipelining may not significantly increase the diameter of the pipe, which can be a limitation in some instances.

Dependent on Pipe Condition: It works best for pipes with minor to moderate damage and may not be suitable for severely collapsed pipes.

Potential for Chemical Exposure: During the curing process, chemical emissions from the resin may occur, although modern formulations aim to minimize this impact.

Choosing the Best Option

For your pipe repair needs, weigh some essential considerations before deciding between pipe bursting and pipe lining. Let’s detail these considerations to help you determine the optimal solution for your situation.

The Extent of Damage

Before choosing a repair method, assess the severity of pipe damage. Pipe bursting is ideal for significant issues such as collapses. In contrast, pipe lining is more suited for minor to moderate damage like pipe leaks and corrosion, offering practical solutions without extensive excavation.

Pipe Material and Diameter

Consider the compatibility of your existing pipe material with each method. Pipe bursting can accommodate various materials and offers significant diameter upgrades, whereas pipe lining is versatile but may not significantly increase pipe diameter, making it suitable for more minor repairs.

Budget and Cost Considerations

Evaluate the upfront costs and long-term savings associated with each method. While pipe bursting may have higher initial expenses due to equipment and labor, it can lead to reduced future maintenance costs and increased durability. Pipelining is generally more cost-effective for more minor repairs, offering a balance between affordability and effectiveness.

Long-Term Goals and Durability

Determine your priorities regarding long-term durability and capacity improvements. Pipe bursting provides robust, long-lasting solutions by replacing old broken pipes with larger, more durable ones, improving flow capacity and reducing the risk of future failures. While effective for moderate damage, pipelining may offer a different level of diameter increase or structural reinforcement.

Environmental Impact and Regulatory Compliance:

Consider the environmental implications and ensure compliance with local regulations. Both pipe bursting and pipe lining are environmentally friendly alternatives to traditional excavation methods, minimizing disruption and environmental impact. However, it’s essential to manage emissions during pipe lining curing and responsibly dispose of materials in pipe bursting, aligning with sustainability goals and regulatory standards.

Making the Right Choice: Pipe Bursting vs. Pipe Lining

In conclusion, pipe bursting vs pipe lining examination offers viable solutions for pipe repairs without extensive excavation. The choice between the two depends on the specific circumstances of your project, budget constraints, and long-term goals. You can guarantee successful pipe rehabilitation and make an informed decision by speaking with a competent trenchless technology consultant. Remember to include not just the immediate expense but also the long-term advantages and possibilities for savings in upkeep and future repairs when selecting between pipe bursting and pipe lining.

Rapid Rooter provides efficient pipe repair services in Danbury, CT, through expert damage assessment, tailored solutions for various pipe materials and sizes, cost-effective options, durable long-term results, and environmentally friendly practices.